Automated & scalable production of top quality dentures

FIDENTIS was at IDS 2025

Research Partners and Supporters

Product

FIDENTIS combines the character of precious metal telescopes with the price advantages of hybrid manufacturing. The friction fit can be individually adjusted and precious metal is only used in the fitting surface.

20x

Faster than traditional method

100%

Automated production chain

“The innovation from FIDENTIS sets new standards in dental technology. A true friction fit—individually adjustable and long-lasting.”

Josef Schweiger, M.Sc.

LMU Polyclinic for dental

prosthetics in Munich

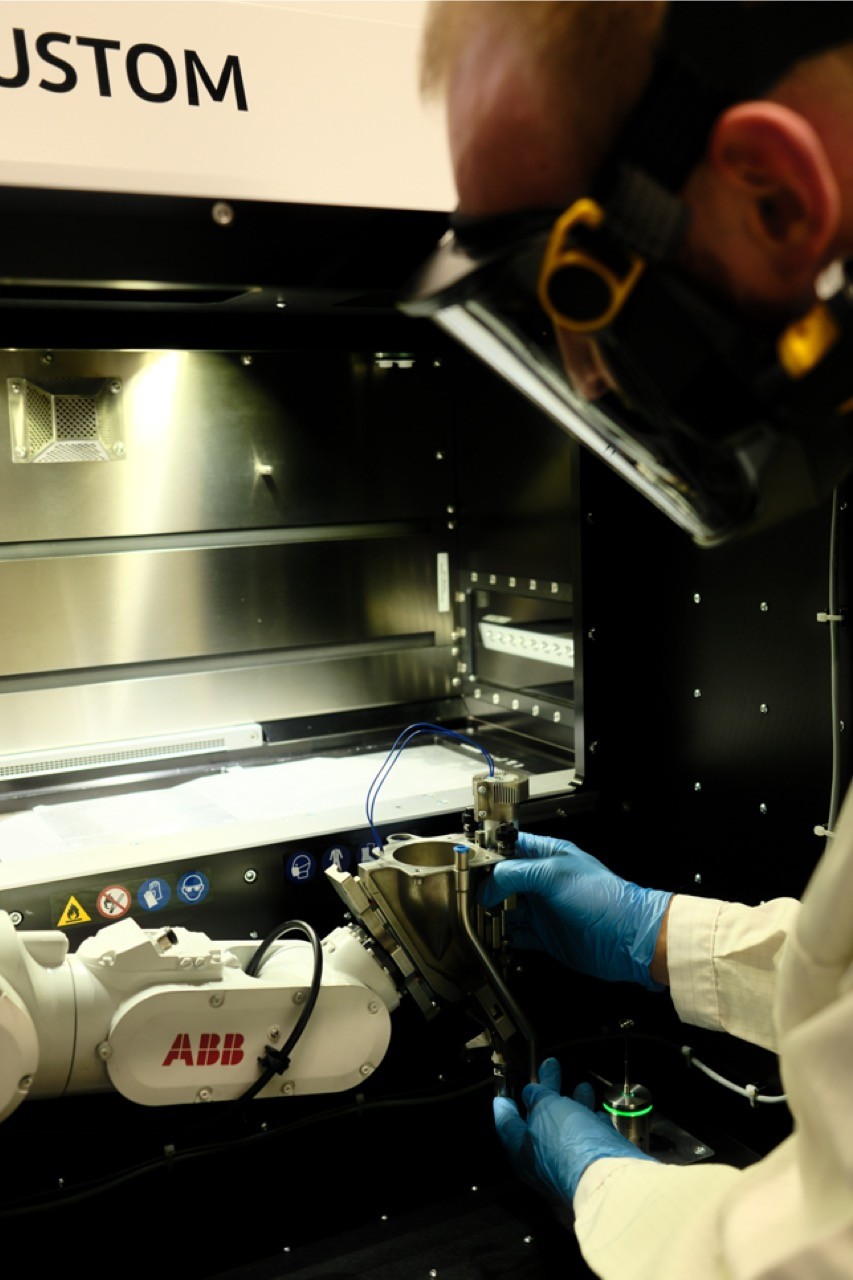

Technology

Discover how we use unique additive manufacturing to scale, and automate the production of the German Crown.

Want to learn more? Book a call now to discuss how we can work together.

Process

We enable a seamless journey for the dental technician, dentist, and patient—from jaw scan to denture production, veneering, and final insertion, ensuring a perfect fit and a confident smile.